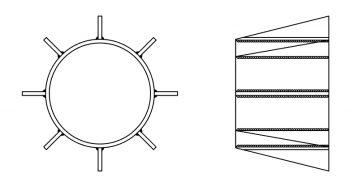

ICP Piles is a high performance and high strength pretensioned spun concrete piles (PHC Piles) that are extensively used in large, complex and technically challenging projects – from high-rise buildings, marine structures to power stations.

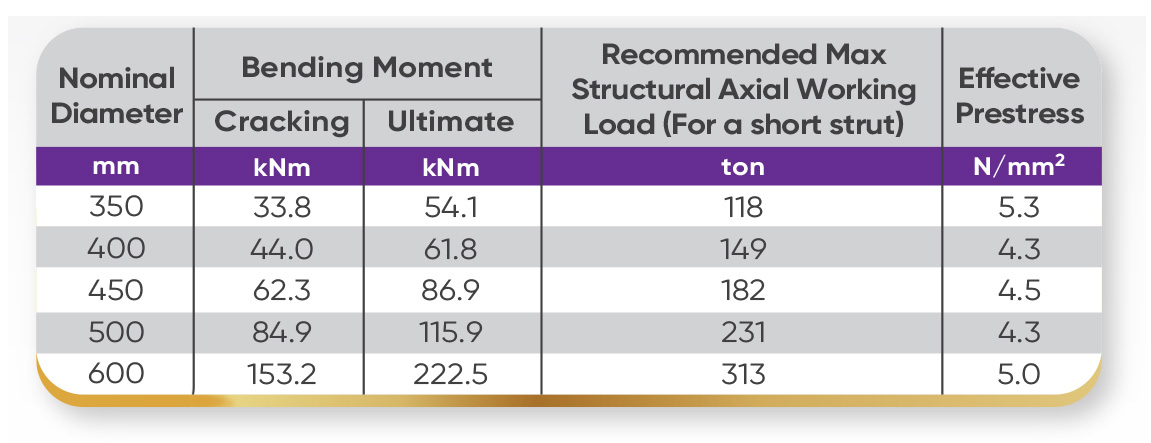

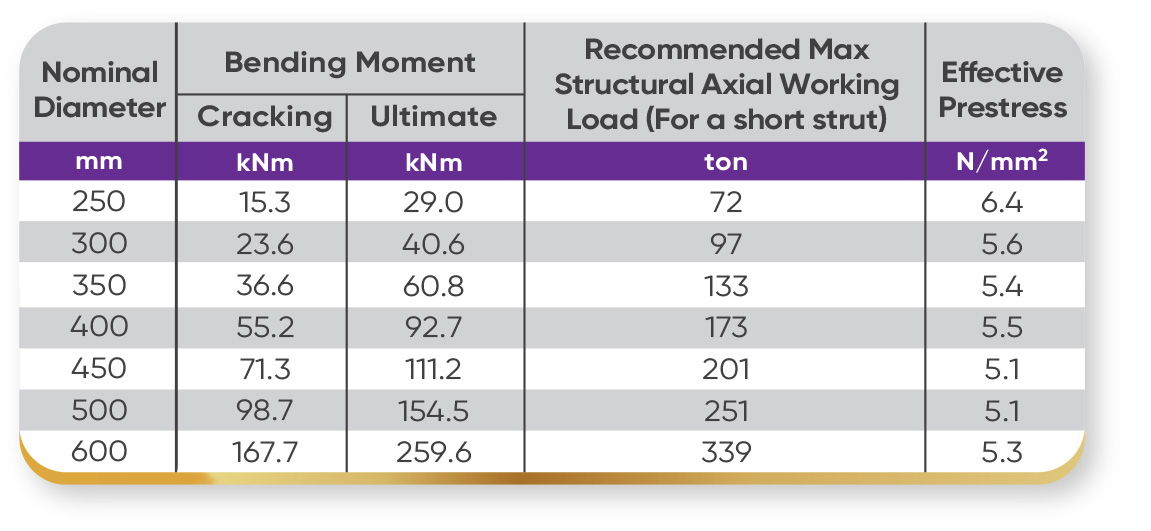

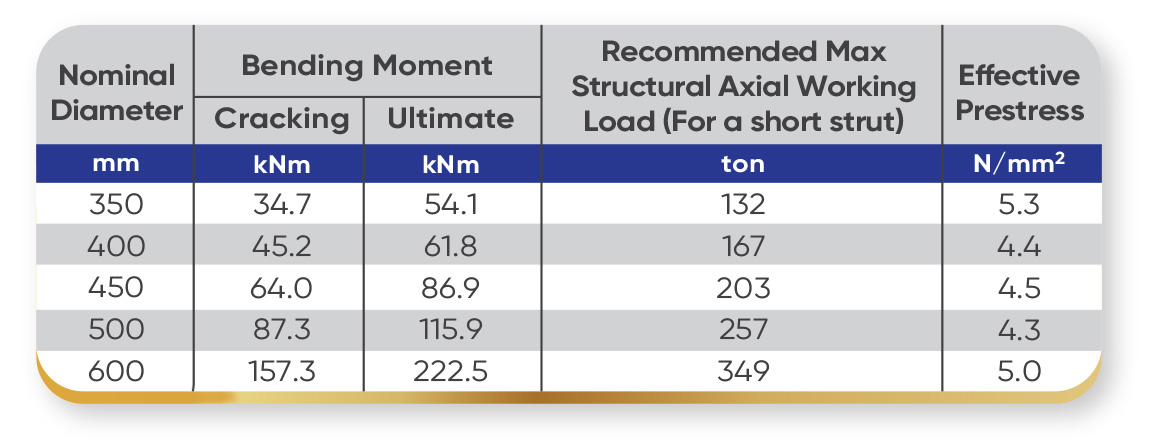

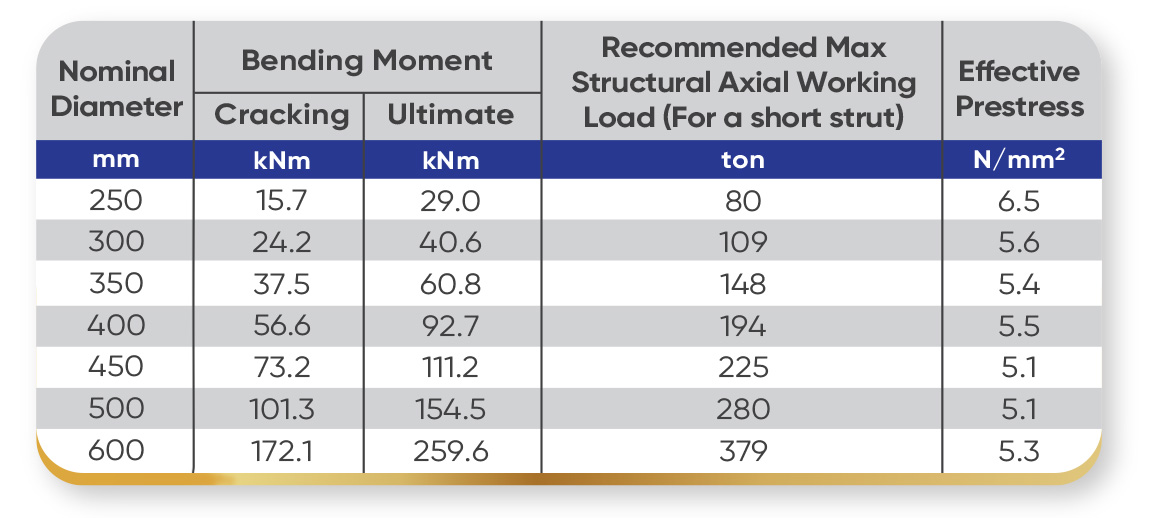

ICP Piles comes in concrete Grade 80, Grade 90 and Grade 100 with lengths varying from 6m to 54m. It also comes in three classes based on the effective prestressed as specified by Malaysian Standard (MS 1314:Part 4:2004). Generally, its prestressed bars are made of high frequency heat-treated bars manufactured to JIS G 3137:2020 standards to ensure only the highest quality and strength.

Download our catalogue for more info on our products.

ICP PILES ATTRIBUTES

- High productivity enables immediate delivery to project sites.

- Piles can be delivered as early as 3 days after casting.

- Customizable to suit any project requirements.

- Spinning process results in denser concrete, giving high resistance to corrosion.

- High strength concrete of up to Grade 100 enables piles to be driven through hard strata, providing a more economical solution.

- Can be manufactured up to diameter 1200mm and a maximum single length of 54m.

- Big diameter piles can be joined in the factory up to the length of 90m.

- Environmental-friendly installation which are noise, pollution and vibration-free using hydraulic jacking pile installing machine.

- Prestressed concrete provides higher bending moment capacity compared to conventional reinforced concrete piles.

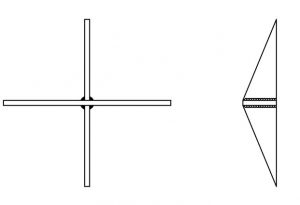

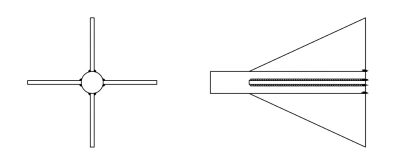

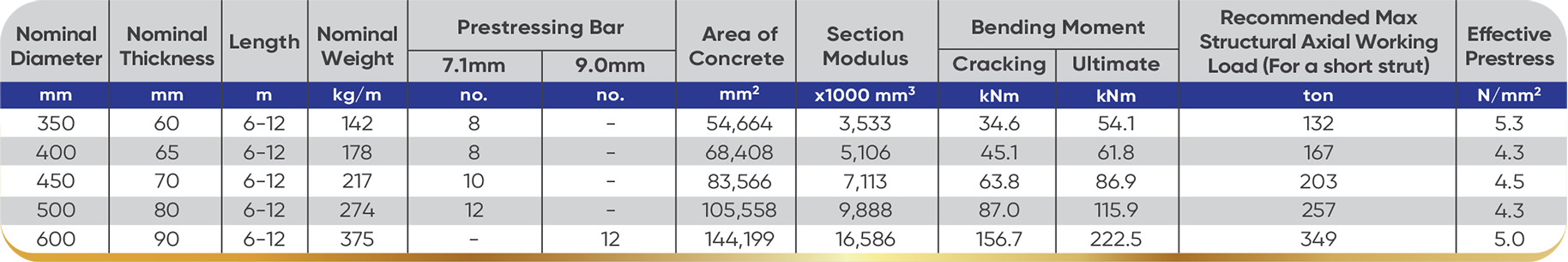

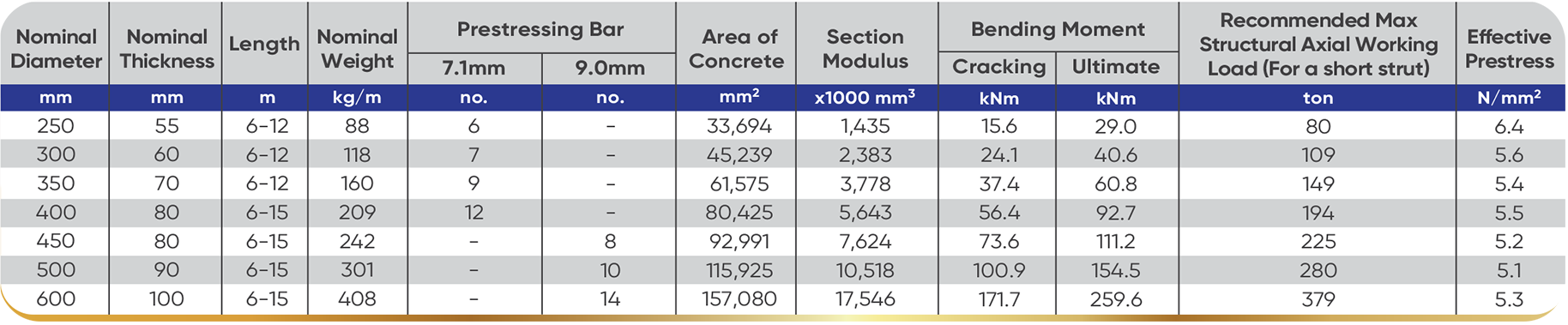

PROPERTIES OF ICP PILES

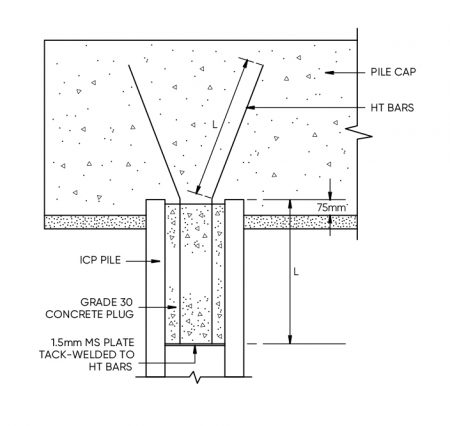

BONDING ICP PILES INTO PILE CAP

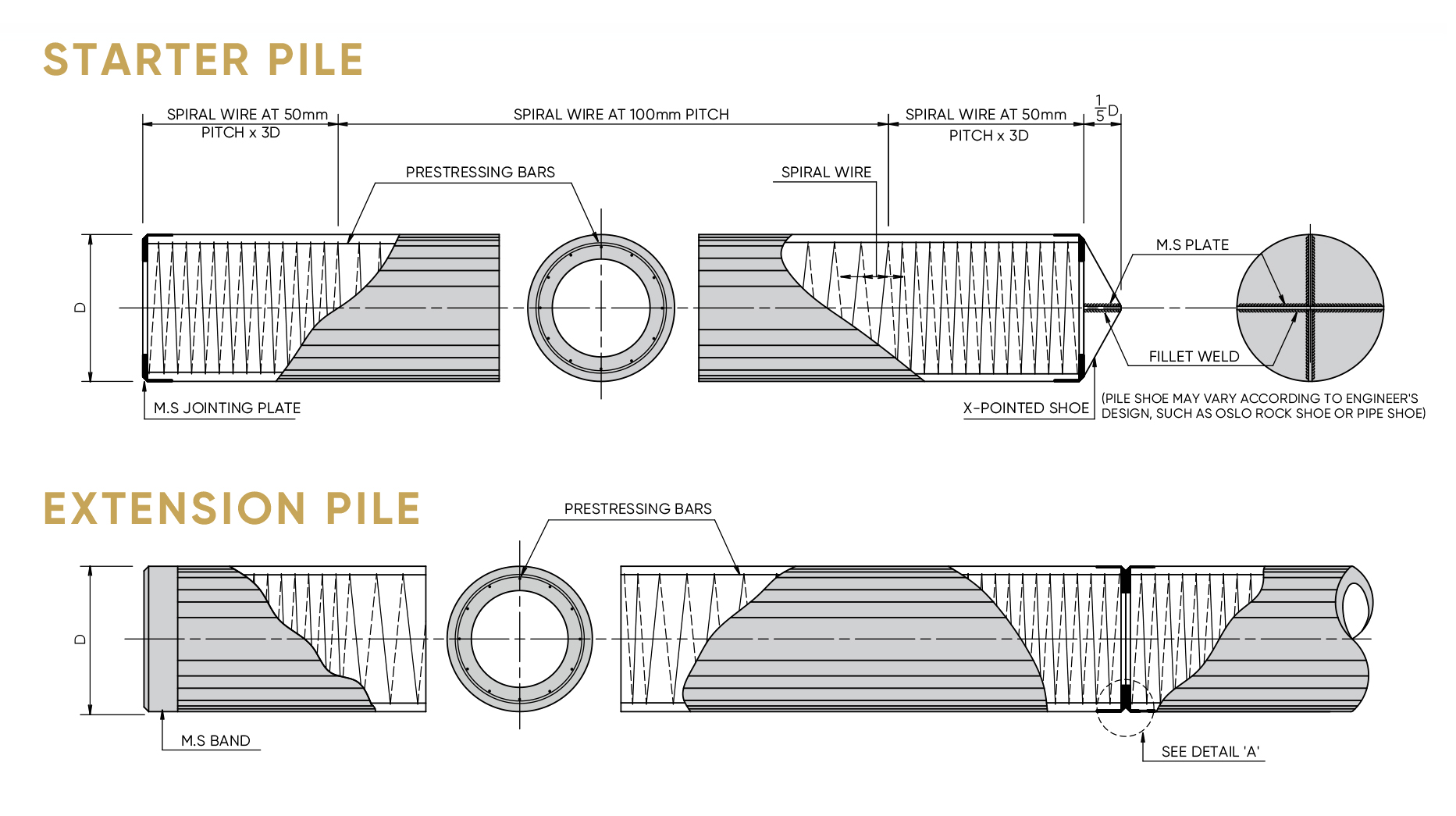

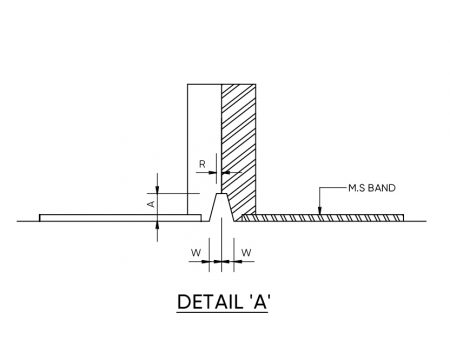

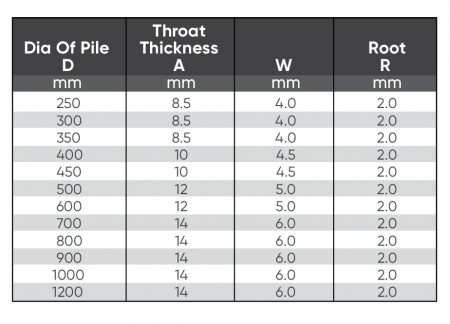

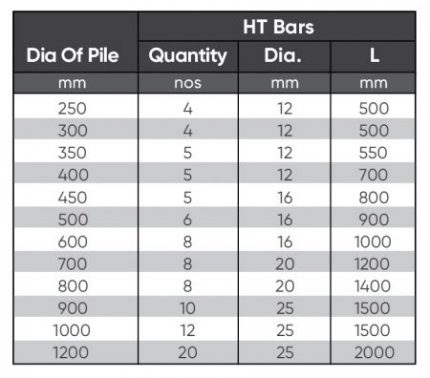

As the PC bars are bonded with concrete, ICP Piles may be cut off at any point. The piles need not be stripped down to expose the bars and can be bonded to the pile cap as shown in the below sketch. If the piles are not subjected to tensile load, the recommended H.T. bars are considered adequate.

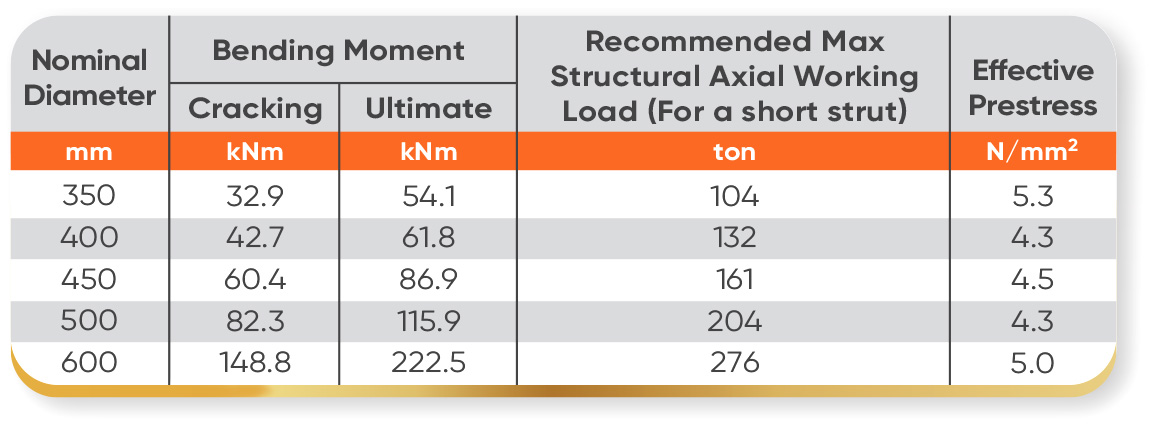

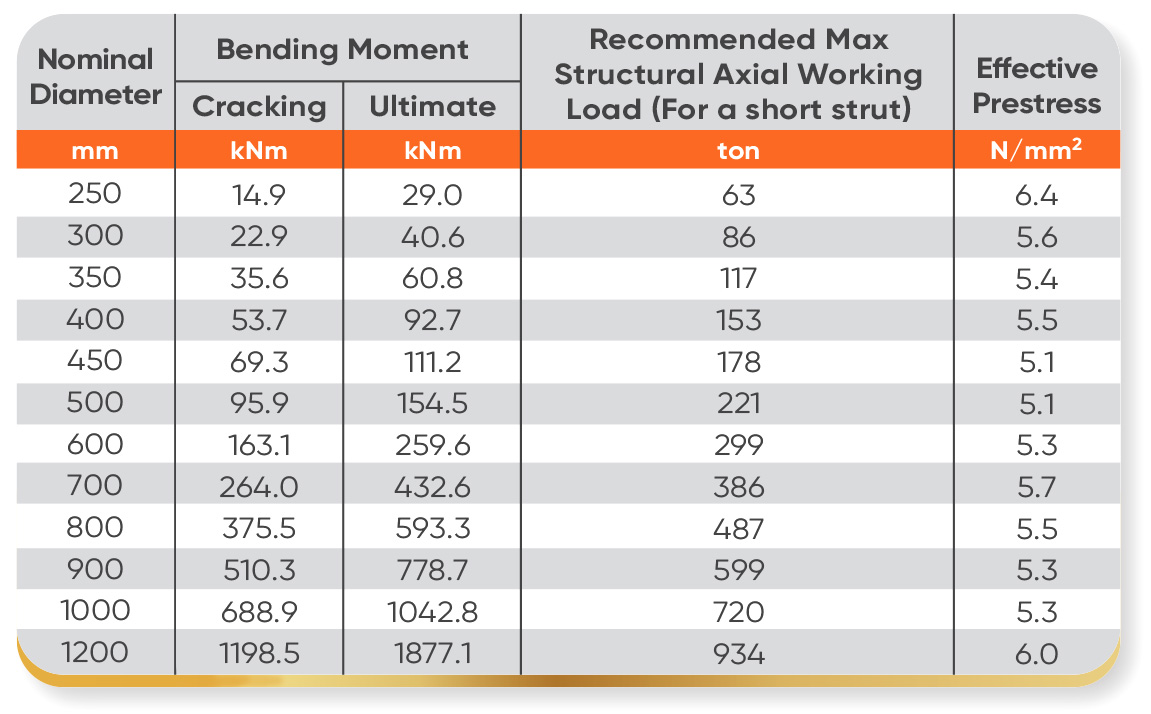

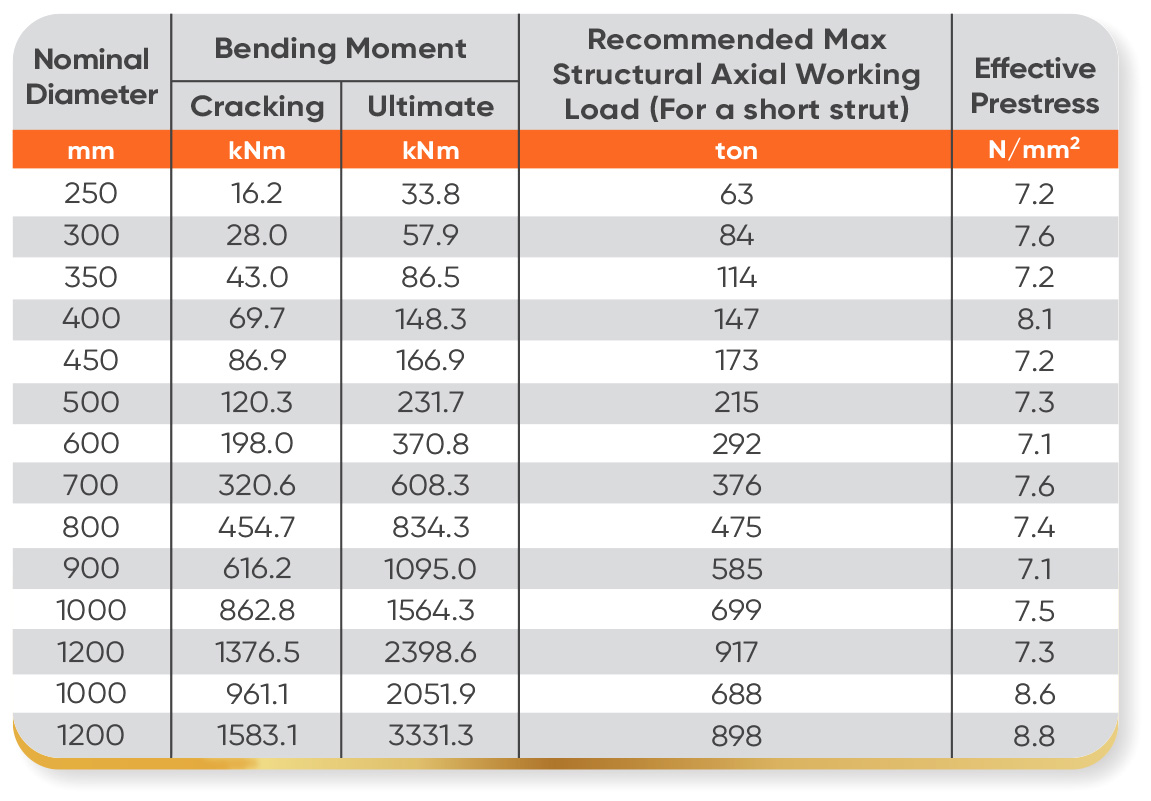

STANDARD GRADE 100 PILES

CLASS A (EFFECTIVE PRESTRESS 4.0 N/mm2)

CLASS B (EFFECTIVE PRESTRESS 5.0 N/mm2)

AREAS OF APPLICATION

Power Stations

High Rise Buildings

Civil Engineering Works

Government Projects

Marine Structures

Harbours

Bridges

Schools

Get in Touch With Us

Feel free to contact us with questions, partnership proposals, product inquiries, or just to say “hi.”